FA EAP

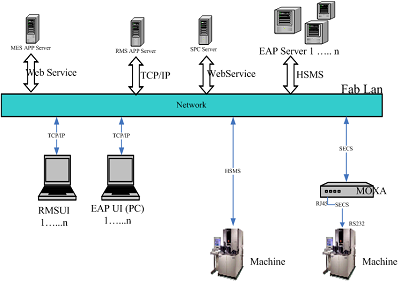

The equipment automation (EAP) solution provided by FA Software is based on the FA SECS Driver and development tools with independent intellectual property rights of FA Software.

By introducing FA EAP, it is possible to reduce the manual operation of the equipment, simplify the operation process, avoid miss-operation, and improve the productivity of the site.

FA EAP can realize automatic TrackIn and TrackOut operations in MES; it can automatically detect whether MES Recipe matches the equipment, and automatically download the recipe to the machine remotely; it can automatically send information such as Lot ID, number of wafer, and Slot ID to the equipment; can automatically control equipment, automatically collect machine parameters, automatically collect machine status, etc.

FA EAP provides various equipment control logic, as long as the target equipment supports the corresponding instructions, such as start processing, end processing, loading, unloading, etc.

FA EAP provides various equipment control logic, as long as the target equipment supports the corresponding instructions, such as start processing, end processing, loading, unloading, etc.

Corresponding interface manual of the equipment needs to be provided to FA Software in order to determine the control logic supported by the equipment.

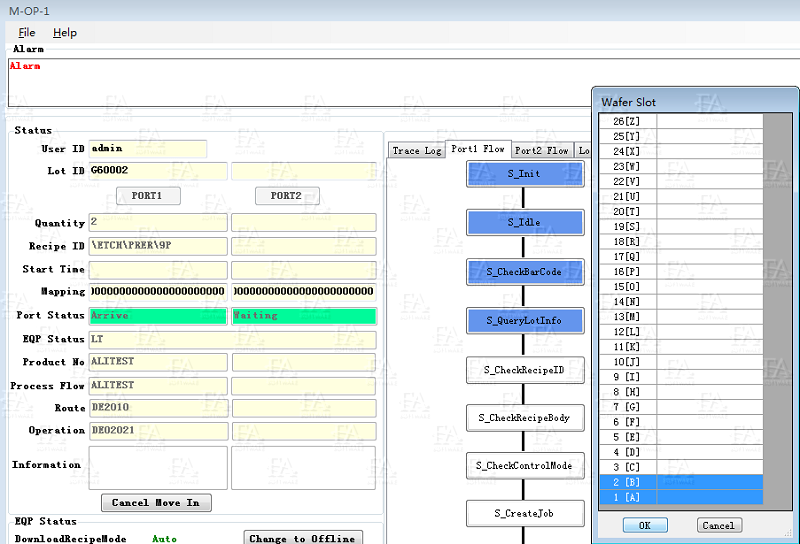

On the operation interface, there are various information provided for the operator, including the equipment status information, Lot information, etc., and other related information is displayed. Also, next operation is prompted.

On the operation interface, there are various information provided for the operator, including the equipment status information, Lot information, etc., and other related information is displayed. Also, next operation is prompted.

Operator selects Lot on the interface for operation, and the collected data can be displayed on the interface for the operator to confirm.

On the operator interface, you can implement some MES functions, such as Hold, Release, Skip and other functions.

Production data for production equipment and measurement data for measuring equipment can be collected automatically.

Production data for production equipment and measurement data for measuring equipment can be collected automatically.

According to the requirements of the MES system, upload relevant data to the MES system.

The calculation and format conversion of some data can be realized according to the setting.

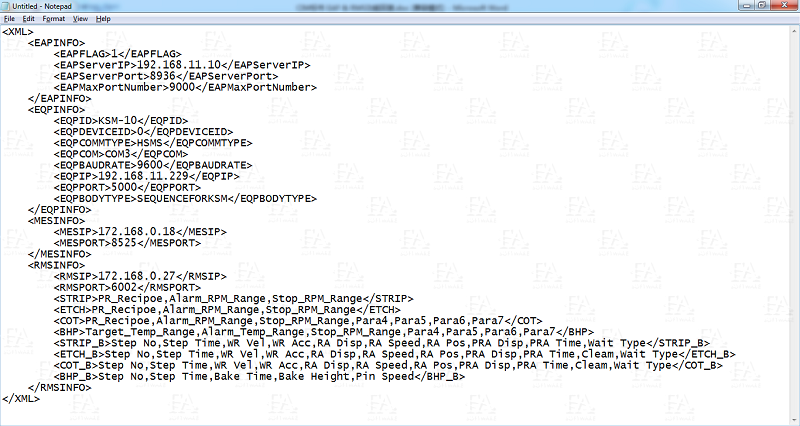

FA EAP can upload the recipe body defined by the engineer in the RMS system to the machine, and check the important parameters of the recipe body. If it does no...

FA EAP can upload the recipe body defined by the engineer in the RMS system to the machine, and check the important parameters of the recipe body. If it does not match, alarm will be triggered according to the user's requirements and it is not allowed to start operations.

FA EAP can also download the Recipe Body on the equipment to the RMS system, and compare the current Recipe Body on the equipment with the active version of the Recipe Body in the RMS system.

TrackIn or TrackOut can be made at the corresponding time according to customer requirements.

TrackIn or TrackOut can be made at the corresponding time according to customer requirements.

Under special circumstances, you can hold Lot on the MES, for example, when some data exceeds the Specification Limit.

You can check whether Lot is allowed to be produced in the current equipment to avoid using the wrong equipment.

FA EAP obtains the equipment recipe through the MES system, and converts the name and path of the equipment recipe in the MES according to the set rules so that the equipment can identify the recipe provided.

FA EAP obtains the equipment recipe through the MES system, and converts the name and path of the equipment recipe in the MES according to the set rules so that the equipment can identify the recipe provided.

If batch operation is performed in MES, FA EAP can automatically select the equipment recipe for the entire batch (the same recipe is used for lot in the same batch).

According to the operating status of the equipment, the equipment status in the MES system is updated in real time.

According to the operating status of the equipment, the equipment status in the MES system is updated in real time.

It can be integrated with FA RMS (or other RMS) to enable RMS functionality.

It can be integrated with FA RMS (or other RMS) to enable RMS functionality.

A variety of message logs are available, including those that communicate with devices, with MES or other systems.

A variety of message logs are available, including those that communicate with devices, with MES or other systems.

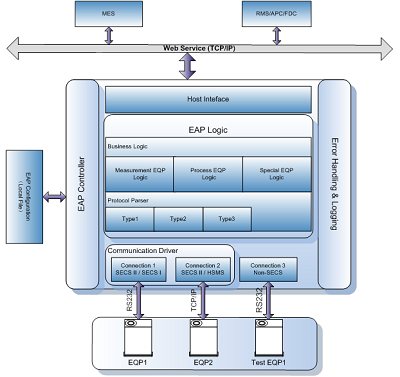

The FA EAP system and its supporting FA SECS Driver and SECS Tool tool are based on Microsoft .Net framework, which has good scalability and easy maintenance.

FA EAP supports multiple communication methods, such as: Web Service (TCP/IP), RV/TIBCO, MSMQ, Tuxedo, etc.

In terms of communication protocol, it supports standard semiconductor communication protocols such as SECS I/SECS II/HSMS.

The FA EAP system is scalable and can be flexibly equipped with EAP servers according to the number of equipment on site and actual needs.

For RS232 interface equipment, it can be connected to the network after conversion through a multi-port MOXA card.

FA EAP system supports redundant configuration, that is, if any EAP server fails on site, its processing will be automatically switched to another EAP server.