FA MDM

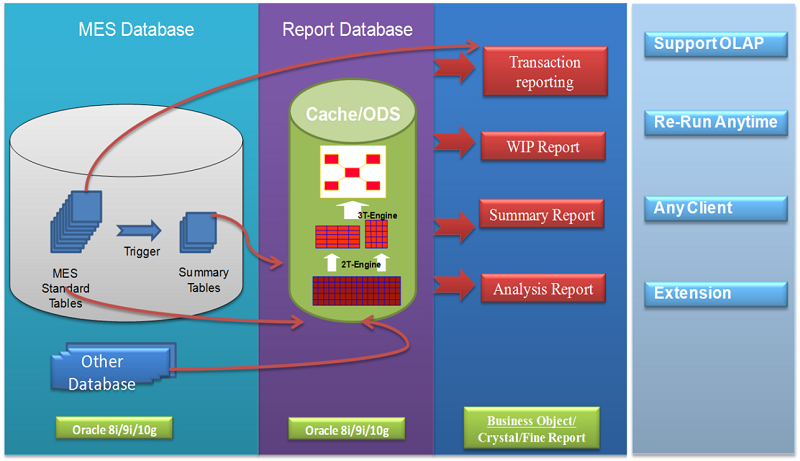

FA MDM (Manufacturing Data Mart) provided by FA Software is a manufacturing process data platform that is responsible for collecting various production-related data in the enterprise and storing it in a dedicated database after sorting. Users can use data display tools (such as report tools) to easily display relevant data.

Different from the data center where the enterprise data warehouse (Data Warehouse) uniformly controls multiple topics, FA MDM is a simple form of data warehouse, which is positioned in the collection and arrangement of data related to a single production within the enterprise.

The data source can be from internal business systems (such as MES, SPC, EAP, etc.), relevant data in the central data warehouse, or external systems.

Supports crawling data from related systems at intervals set by the user, such as minutes, hours, days, etc.

Ability to define the start and end time of factory shifts for data collection and analysis by shift.

FA MDM currently supports hierarchical data extraction and processing. FA MDM at the headquarters can extract and process the FA MDM data that has been processed by each production base again to comply with enterprise data processing standard.

FA MDM has been integrated with FA Software's own products, which can provide all kinds of data required for production floor to the greatest extent.

FA MDM has been integrated with mainstream ERP systems on the market, including SAP, Oracle, UFIDA, Kingdee, etc., and can obtain and integrate ERP data to provide more comprehensive data for management and use.

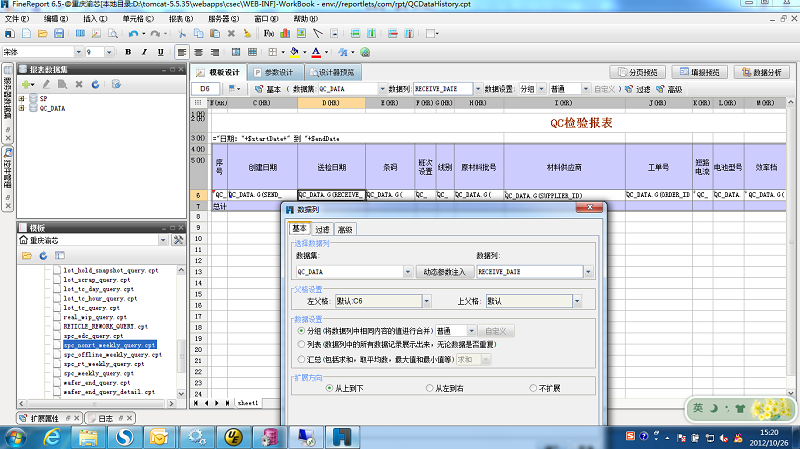

FA MDM supports a variety of front-end presentation tools. FA software recommends using FineReport. Users can also use other reporting tools such as Crystal Report.

FA MDM also supports the connection of various enterprise internal systems to obtain the production-related data it needs.

FA MDM also supports MS Office to directly display the data in FA MDM in MS Office through external data sources.

| Transaction processing reports, such as reports for creating batches | Accident report --- batch scrapped, suspended batch, alarm report and out of control report | Management report --- batch completion status, output, number of products in process, equipment utilization, etc. |

| Historical report --- batch processing history, batch history information, etc. | Yield report --- yield information for the batch, etc. | Provide an expandable report data storage structure, and expand data mining and analysis in the future |

| Support query conditions based on days, weeks, months, and custom periods | Support query based on factory, product and other conditions | Support PO detailed information and current progress status query |

| Support detailed information of work order and current progress status query | Support exporting report related information to Excel | Support product, process route, process, equipment, BOM, Bin, Defect, customer, user and other related information query |

| Support query conditions based on days, weeks, months, and custom periods | Support the display of raw data used for analysis | Support the calculation of statistical parameters such as product process capability (Ca/Cp/Cpk) and variation CV according to Lot/Wafer |

| Support completed PO/work order information query | Support query conditions based on days, weeks, months, and custom periods | Support query based on factory, product, process route, process, process step and other conditions |

| Support production performance query for each process | Support the query of the working status of each process | Support Lot/Wafer manufacturing history query |

| Support packaging and shipping information query | Support for outsourcing Lot information and status query | Support raw material usage status inquiry |

| Support process inspection status query | Support abnormal occurrence history and summary query | Support automatic generation of WIP batch reports that have exceeded the delivery cycle |

| Support query conditions based on days, weeks, months, and custom periods | Support query based on factory, product, process route, process, process step and other conditions | Support Lot/Wafer yield query |

| Support each process and every lot Cycle Time query | Support each process and each lot production efficiency query (Process Time/Idle Time/Queue Time/Tact Time/Etc.) | Support Product, Lot, Wafer Defect summary query |

| Support Product, Lot, Wafer Bin level summary query | Support process, product, factory lot scrap information query | Support product cost analysis (that is, the current cost status of each product: calculate the cost of each process, raw material cost, labor cost, etc.) according to the Recipe |

| Support work-in-process Lot Due Time prediction; support the calculation of the start time and end time of the lot unfinished process | Support the traceability analysis of raw materials, that is, it can be traced back to a certain batch of raw materials being used on a certain equipment to complete the processing of a certain Lot or Wafer (including various precious metals, liquids and g | Support lot summary for each process that exceeds the control specifications and limits |

| Support query conditions based on days, weeks, months, and custom periods | Support query based on conditions such as factory, process route, process, process step, etc. | Support equipment utilization rate query for each process |

| Support each process equipment alarm and downtime information query | Support MTTR average maintenance time per equipment/MTBF average time between failures information query | Support analysis condition limitation based on days, weeks, months, and custom periods |

| Support analysis based on conditions such as factories, products, process routes, process, process step, equipment, and process parameters |