MES myCIM

FA Software’s myCIM is a next-generation, workflow-driven MES (Manufacturing Execution System) that maximizes productivity and yield through the implementation of information sharing and process automation in the plant, thereby reducing production costs and improving production management.

myCIM is a comprehensive MES solution with excellent flexibility and scalability, is the first semiconductor industry MES with full independent intellectual property rights, but also one of the most advanced MES products in China. MyCIM's modular design can be combined with different industries and customer needs to meet the needs of customers, resulting in maximum input-output ratios.

After more than 20 years of iteration, myCIM evolved from the original version 1.0 to the latest version 4.0, which supports the production of fully automated FAB plants and a 12-inch chip production line, achieving the high flexibility and personalized production model required by Industry 4.0.

The system setting provides system setting functions for the MES system, including production units, columns, pages, data dictionary, menu settings, etc.,

The system setting provides system setting functions for the MES system, including production units, columns, pages, data dictionary, menu settings, etc., and provides a personalized Dashboard for configuring the system. The system setting module as a standard framework provides basic general functions required by customers. And provides a series of custom extension settings, which is conducive to the rapid construction of applications. Standardize the definition of objects in cross-multi-application programs, support multiple languages and multiple units. Because many elements are customizable, the system becomes more flexible and scalable.

This module allows users to define the product and its corresponding process, including each process step type and related process control.......

This module allows users to define the product and its corresponding process, including each process step type and related process control.

In terms of process definition, the module supports multi-path, and during on-site operations, it can automatically select a path according to preset conditions.

The module also supports various product process control, including Q-Time control (cross-site positive and negative time limit), machine limit, process/equipment limit, pollution level control, and provides various future actions (such as future maintenance, Operation tips, etc.) and so on.

In terms of rework settings, it supports the limit on the number of reworks, and can define multiple levels of rework through the context of the system, such as process step/operation/process/product/batch, etc.

This module can set a collection plan for the data that needs to be collected in production, and can define parameters...

This module can set a collection plan for the data that needs to be collected in production, and can define parameters, parameter sets, collection points, samples and sample points, etc.

Supports data collection according to Job, Lot, and Wafer, and provides Wafer Sampling rule settings, including TOP+N, BOTTOM+N, etc.

The data can be obtained directly from the measuring device through the interface, or the data can be automatically obtained through the file generated by the measuring device.

This module provides the definition of basic equipment information, including the definition of parent-child equipment and......

This module provides the definition of basic equipment information, including the definition of parent-child equipment and multi-chamber equipment.

It provides the establishment and tracking management of the equipment state model, and can realize the state linkage between the parent-child equipment and the multi-chamber equipment, and can support the permission setting of the state switching.

This module contains recipe information for all processes, which can be created and updated. The recipe can be ......

This module contains recipe information for all processes, which can be created and updated. The recipe can be controlled by version, including creation, activation, freezing, cancellation, etc.

It supports the setting of logical recipe and actual recipe (processing parameters), and can be set according to process conditions, and the recipe is automatically selected according to the previous measurement results.

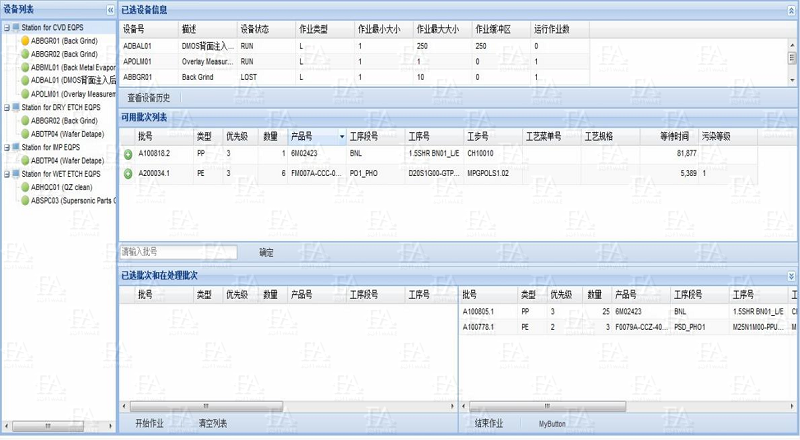

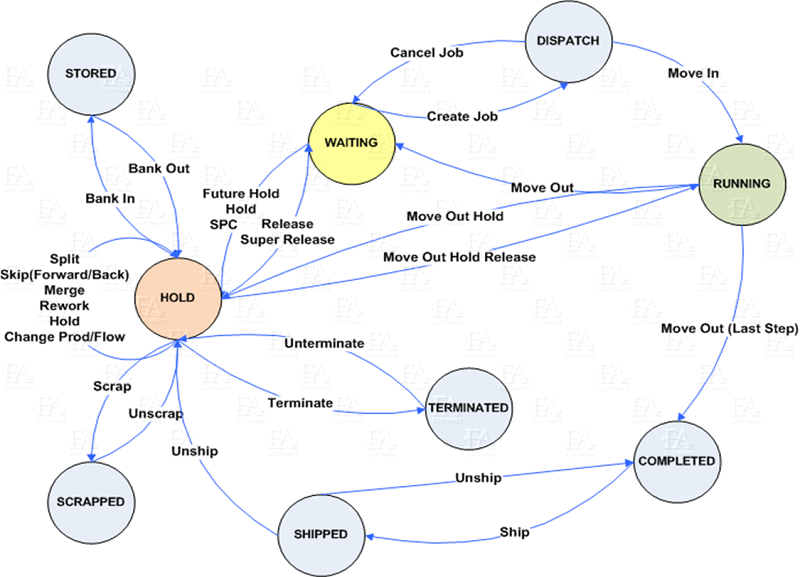

This module manages the processing of the work-in-process, guides the operator to process the product according to the pre-set process requirements, and performs detailed tracking and recording of the processing information.

This module manages the processing of the work-in-process, guides the operator to process the product according to the pre-set process requirements, and performs detailed tracking and recording of the processing information.

One of the most important job management function allows tracking multiple batches to be processed simultaneously, which can be managed and tracked by wafer, provides wafer level historical traceability.

In addition to the commonly used dispatch (Dispatch), batch dispatch (Batch), inbound (Move In), outbound (Move Out), other functions include: split (Split), merge (Merge), hold (Hold), release (Release), skip (Skip), multi skip (Mulit-skip), internal rework (Internal-rework), external rework (External-rework), etc.

This module includes the management of raw material library and auxiliary material library. This module can be used standalone or as an extension of the warehouse management module in ERP via interface provided.

This module includes the management of raw material library and auxiliary material library. This module can be used standalone or as an extension of the warehouse management module in ERP via interface provided.

Support common warehouse management functions: stock in, consume, stock out, cancelling stocks, warehouse definition, store room and shelves, lending, return, scrapping, stock out revise, stock in revise, quality level, freezing, etc

The module includes the management of the raw material library and the auxiliary material library. The module can be used alone or as an extension of the ERP treasury management module to achieve interface functions.

Support common warehouse management functions: storage, use, warehouse exit, return, warehouse definition, storage and shelf, lending, return, scrap, repair out of storage, repair storage, quality level, freezing and other functions

This module supports Cassette type, slot number, life cycle definition, and also supports state model management.

This module supports Cassette type, slot number, life cycle definition, and also supports state model management.

Provide maintenance settings for cassette, support automatic calculation of usage count and usage time, trigger reminders, etc.

This module supports the setting of related attributes of the reticle, such as type, grade, purpose, customer, etc., and can also support integration with E-RACK.

This module supports the setting of related attributes of the reticle, such as type, grade, purpose, customer, etc., and can also support integration with E-RACK.

Support the management of the equipment entry and exit of the reticle, and check whether the reticle is used correctly during batch processing. Provide reticle maintenance management, you can set up a maintenance plan according to the usage count and usage time.

Provide batch experiment management, including dynamic setting of batch process, batch sheet and other functions, support setting and replacing batch process steps, recipes, collection plans and other information, and provide pre-set process approval.

Provide batch experiment management, including dynamic setting of batch process, batch sheet and other functions, support setting and replacing batch process steps, recipes, collection plans and other information, and provide pre-set process approval.

Provide Workflow editing tools to set the OCAP process. The process nodes include weight, add volume, remarks, batch release, etc., according to the process settings for approval and linkage with MES functions.

Provide Workflow editing tools to set the OCAP process. The process nodes include weight, add volume, remarks, batch release, etc., according to the process settings for approval and linkage with MES functions.

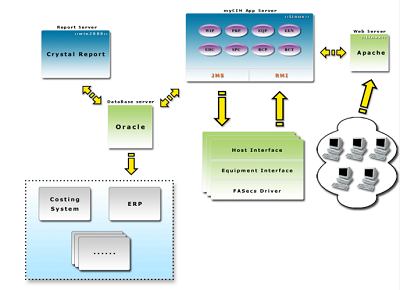

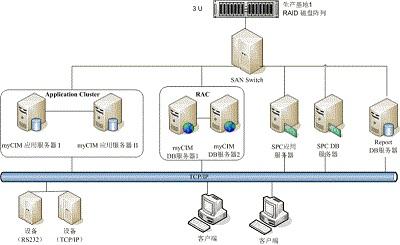

The myCIM system adopts a microservice architecture based on Workflow, which has the characteristics of high performance, high stability, and high scalability. Multiple server instances can provide services at the same time, and provide simultaneous processing capabilities for high concurrent requests through load balancing technology, effectively avoiding the impact of excessive server operating pressure on system services; flexible microservice architecture is also very easy to integrate external systems and services, and provide interface integration testing and log traceability, enabling the system to deliver iterations quickly.

Thanks to the microservice architecture, myCIM can run on Linux/Unix or on Windows. It can support x86 and ARM servers, as well as containerized deployment, speeding up the rapid iteration of development and testing.

The number of myCIM application servers can be increased or decreased at any time depending on the business volume. It supports LVS technology to achieve load balancing.

In terms of database, myCIM supports Oracle RAC technology, which can realize high-concurrency business processing. It also provides good support for open source databases such as PostgreSQL, providing customers with more choices.