FA SPC

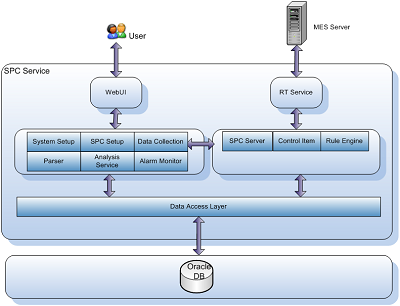

FA SPC is a BS-based statistical process control system (SPC) developed by FA Software. It can monitor the production process online or offline, and discover possible quality problems in the production process in time to help user to control and improve products quality.

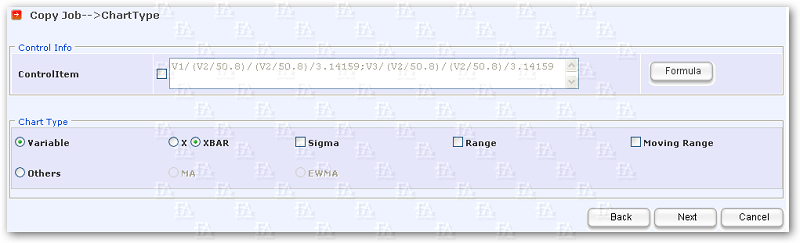

FA SPC supports both counting and metered SPC control charts, including, but not limited to: counting mean-extreme control chart (XBar-R chart)/average-standard deviation control chart (XBar-S chart), single-value-moving extreme control chart (X-MR chart), metered nonconformity rate control chart (P chart), nonconformity number of product charts (NP charts), defect control charts (C charts), unit defect control charts (U charts), and other SPC charts (e.g. Box Plot, Histogram, Scatter, Pareto, Normal Risky Plot, etc.), while FA SPC can take measures such as alarms, sendmails to relevant departments, Hold Lot, Hold Equipment, etc.

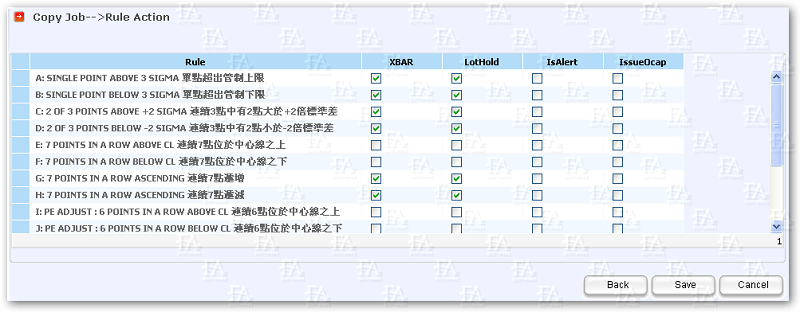

In terms of SPC monitoring rules, FA SPC supports user-defined SPC Rules in addition to universal Western Electric Rules and Nelson Rules.

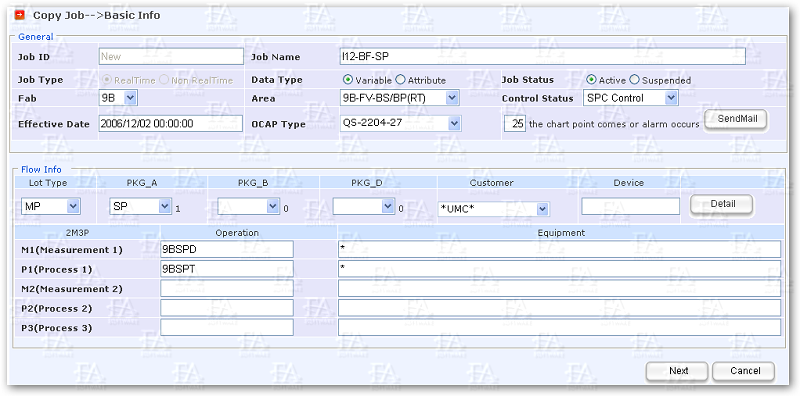

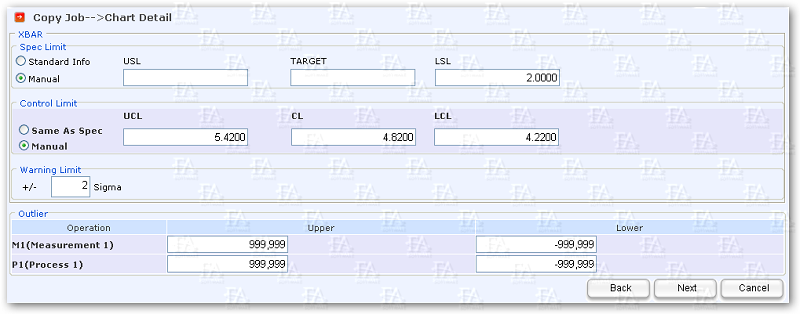

FA SPC introduces the concept of SPC Job. All monitoring is based on SPC Job. Each SPC Job includes data filtering, specification limit setting, SPC Rule setting and out-of-tolerance action definition.

FA SPC introduces the concept of SPC Job. All monitoring is based on SPC Job. Each SPC Job includes data filtering, specification limit setting, SPC Rule setting and out-of-tolerance action definition.

SPC Job supports multi-layered SPC Inline monitoring by Wafer or Lot or Batch.

Each SPC Job supports one or more control charts, and each chart can be monitored using one or more SPC Rules.

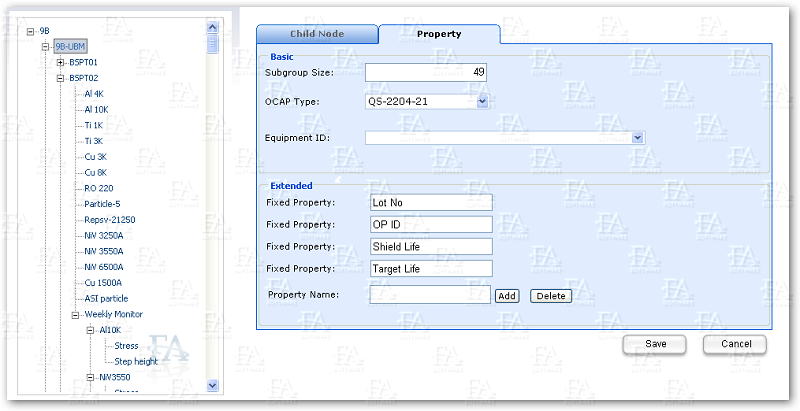

This feature is used to set up a collection plan (or Offline SPC) for "non-product data", including device-related data and environmental data.

This feature is used to set up a collection plan (or Offline SPC) for "non-product data", including device-related data and environmental data.

Supports custom NonRT data collection hierarchical relationships;

Supports defining the type of data collection: counting, metering, and defining sample numbers and subgroups of data.

The FA SPC is not tied to Western Electric Rules and Nelson Rules, and the Rule in the system can be customized by the user.

The FA SPC is not tied to Western Electric Rules and Nelson Rules, and the Rule in the system can be customized by the user.

You can specify Rule's ID, Name, and so on when defined, and a Rule can contain one or more sub-Rules for greater flexibility.

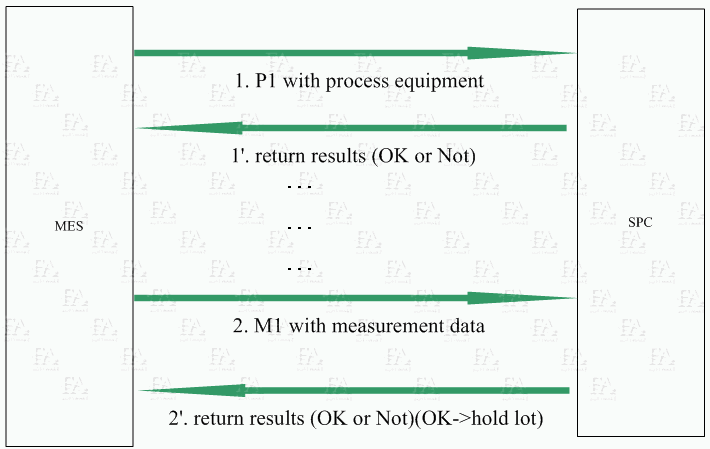

RT is an abbreviation for Real Time.

RT is an abbreviation for Real Time.

RT Service is a Web Service interface provided by FA SPC and is the entry point for MES or other system data into FA SPC.

RT Service not only accepts the data, but also checks the data according to the settings of the pre-SPC Job, such as OOS/OOC, and returns the processing results and required actions to systems such as MES, returning actions such as Hold Lot/Hold Equipment.

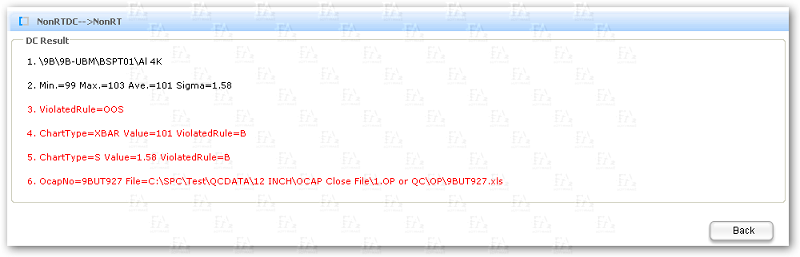

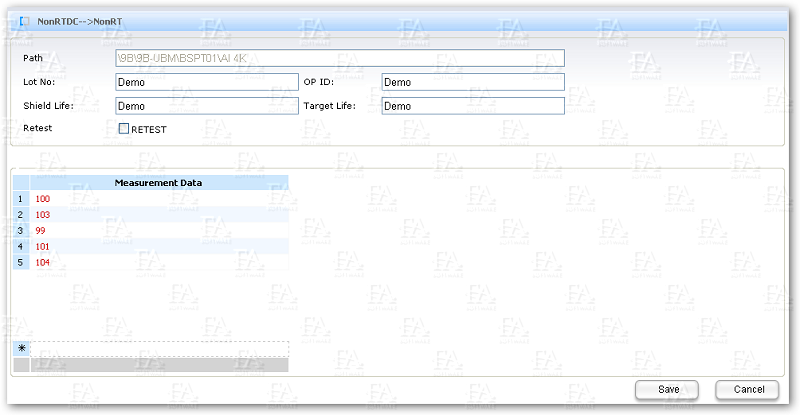

As set by NonRT Setup, operators use NonRT DataCollection to collect Offline data.

As set by NonRT Setup, operators use NonRT DataCollection to collect Offline data.

The system supports a variety of data collection methods: manual entry, file import, access to data from devices via RS232 or TCP/IP interfaces, etc.

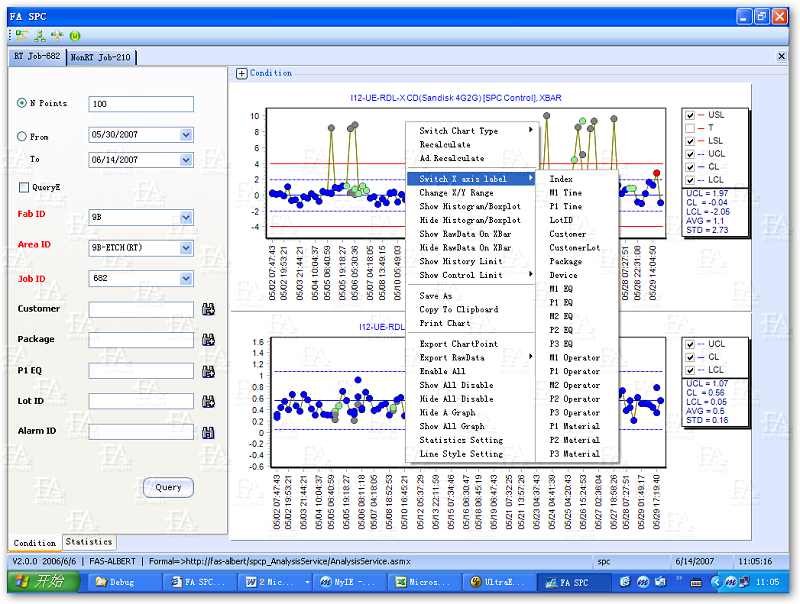

SPC control chart analysis graphically displays the SPC data that has been collected.

SPC control chart analysis graphically displays the SPC data that has been collected.

FA SPC provides a wealth of query and filter conditions to facilitate the extraction of qualified data for display.

Different colors and shapes are used to represent Chart Points in different states: normal point (Normal), abnormal point (Alarm), processed abnormal point (Fixed), violation of rule but not requiring alarm, and comment on this point, and so on.

More than 20 operations can be performed on Chart and Chart Point.

The system provides automatic recalculation function, can automatically calculate the upper and lower limits of control according to the user's preset, and can be integrated with the approval system.

SPC provides a wealth of report analysis, including job setting query, violation point query, CPK query, etc.

SPC provides a wealth of report analysis, including job setting query, violation point query, CPK query, etc.

FA SPC uses Microsoft .Net architecture, which can be deployed on any server running Windows and supports Windows Server 2012 and above.

Microsoft's ClickOnce technology and B/S technology are used in the development technology, and users can access the system through a browser.

Oracle was used as the system's database engine.

The number of FA SPC application servers can be increased or decreased at any time depending on the business volume, and load balancing can be achieved.

Supports Microsoft's NLB, which can realize load balancing of SPC application servers.

In terms of database, FA SPC supports Oracle RAC technology, which can realize high-concurrency business processing.